Habitat’s Air-Lock Linkage System

Overview

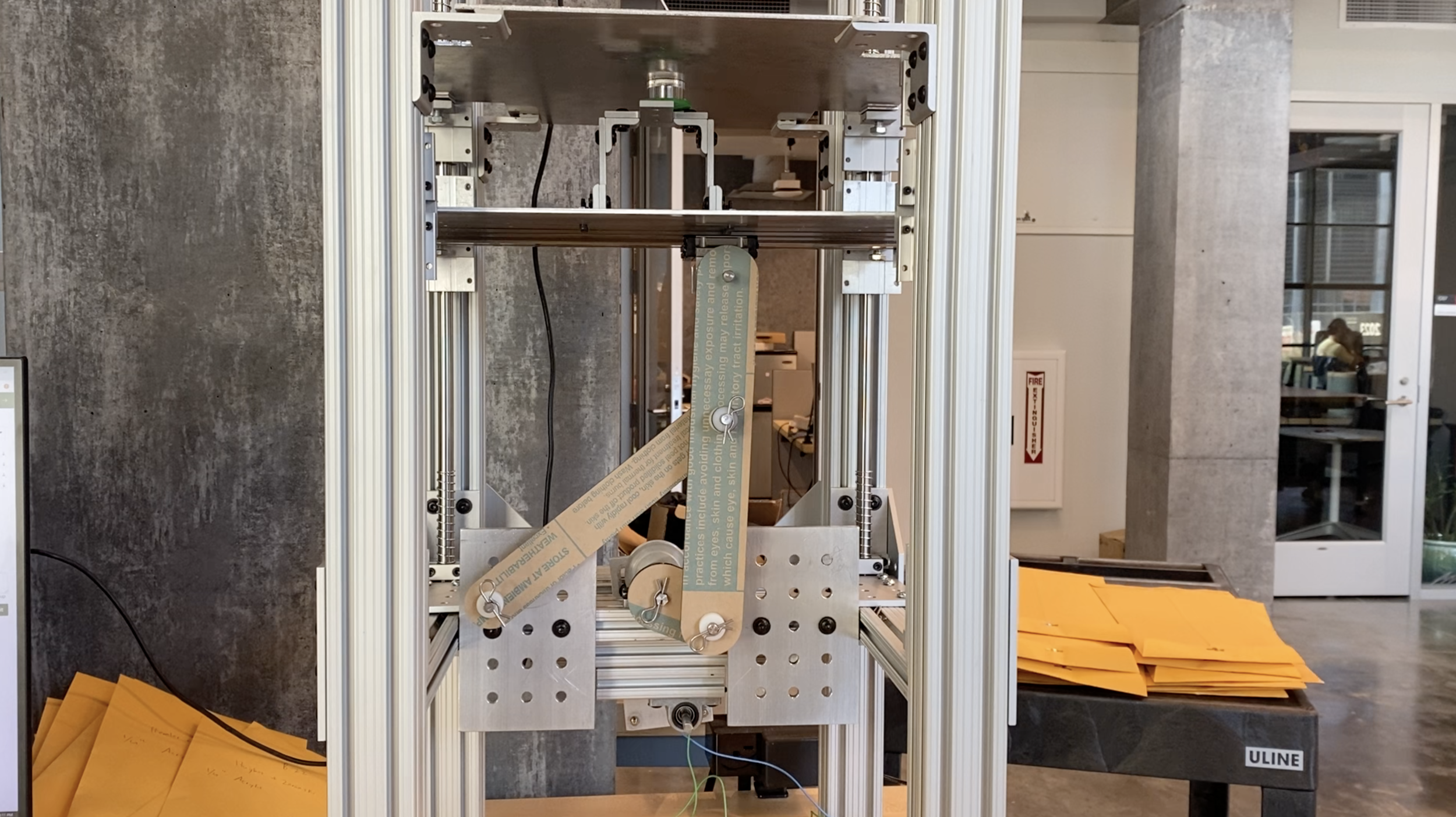

Assigned as the first project for Engineering Design 1 in Fall 2020, this project tasked us with designing a four-bar linkage system that could press a button for an extended period of time. In order to maximize this amount of button pressing time, we had to optimize the geometry of the linkages by adjusting their lengths. In addition to considering the motion of the linkage system, there were some geometric constraints as well that limited the types of configurations available. From a front view, no part of the linkage system was allowed to extend past 6in. below the crank-shaft, 22in. above the crank-shaft, or 6in. to either side of the crank-shaft. In addition, the starting position had to leave at least a 2in. gap between the bottom of the button and the top of the push plate.

While completing this project, my partner and I utilized many different online four-bar linkage simulators as well as SolidWorks motion studies to determine the optimal proportion of each link length to the crank arm. Using data from the motion study, we developed a MATLAB script that would tell us what percentage of the total time the linkage system would be pressing the button. Although we were not able to incorporate it into our final design, my partner and I continued this idea of trying to optimize the link lengths for this project in our Four-Bar Linkage Optimization Project. In addition to using motion studies, we also determined the viability of our design through hand calculations of internal stresses and SolidWorks FEA.

For more information about the design and analysis process click the button below for a pdf of the final report.