Automated Blinds Actuator

Overview

The main idea behind this project was geared towards improving a daily task that our client had trouble with due to their disability. My group’s client, Elaine Houston, had trouble accessing and actuating her blinds in order to raise or lower them making it difficult for her to enjoy the sun during the day but also have privacy at night. In addition, her guide dog oak is a huge part of her life so we wanted to incorporate this aspect into the design as well.

Mechanical Design

The main aspect of this project was interfacing with the ball chain used to raise and lower the blinds. In order to do this, we incorporated a height adjustment system, chain tensioning system, and a gear that mounted to the motor.

Electronics

A button was used as the main input for raising and lowering the curtains. This button was large enough so that Oak could press it on command and made modular so that it could be placed anywhere. In addition, voltage regulators and clever circuit design were incorporated to reduce the number of power cables needed for operation.

Mechanical Design

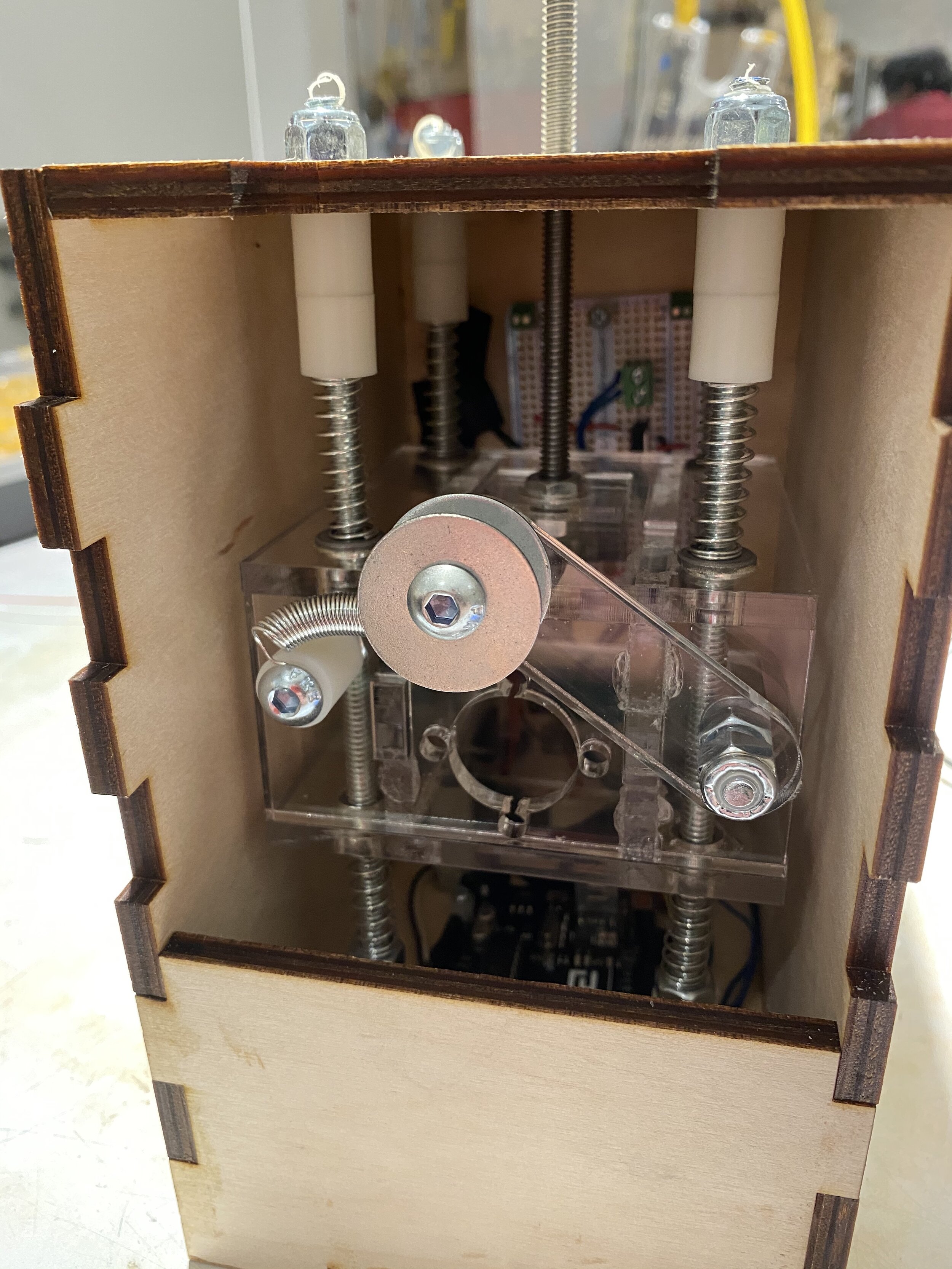

The gear mechanism pictured above meshes with the ball chain connecting it to the motor. While we were unable to get an image of this mechanism connected to the motor due to shipping delays, this image still shows how the axle of the motor connects and rotates the gear. The grooves in the gear are circular in shape to help improve meshing with the ball chain when fitting.

Shown above is the ball chain tensioning mechanism comprised of a link and a spring. When the ball chain is fit around the meshing gear attached to the motor, the spring pulls the link creating tension in the ball chain. Use of a spring ensures that the motor won’t break the ball chain if the curtain gets stuck.

Depicted here is the positioning mechanism that raised and powered the height of the motor to the approximate height of the ball chain. Not pictured is an acrylic laser cut wheel with a nut glued in the center. When threaded onto the rod, this nut would be tightened against the second nut shown in the image to produce a rigid connection allowing for easier rotation of the threaded rod to adjust the final height of the ball chain gear.

Electrical Design

The gear mechanism pictured above meshes with the ball chain connecting it to the motor. While we were unable to get an image of this mechanism connected to the motor due to shipping delays, this image still shows how the axle of the motor connects and rotates the gear. The grooves in the gear are circular in shape to help improve meshing with the ball chain when fitting.

Shown above is the ball chain tensioning mechanism comprised of a link and a spring. When the ball chain is fit around the meshing gear attached to the motor, the spring pulls the link creating tension in the ball chain. Use of a spring ensures that the motor won’t break the ball chain if the curtain gets stuck.